Strategic fleet management drives safety, efficiency and flexibility for Cementation Africa

Cementation Africa’s rock winders are a critical component of shaft-sinking and hoisting operations, engineered to safely and efficiently handle the controlled movement of rock, equipment and materials during shaft development and ongoing underground activities

Cementation Africa’s core activity of opening up ore reserves and underground infrastructure is reflected in the precise drilling of a development end under the watchful eye of an assistant

Cementation Africa completes surface raise drilling installations to create underground-to-surface ventilation shafts, using directional drilling accuracy over depths of up to 1 000 m to precisely hole pilot shafts before reaming large diameter openings

Cementation Africa equips critical underground tips with rock breakers to efficiently manage oversized material and keep tipping operations running safely and smoothly after each truck load

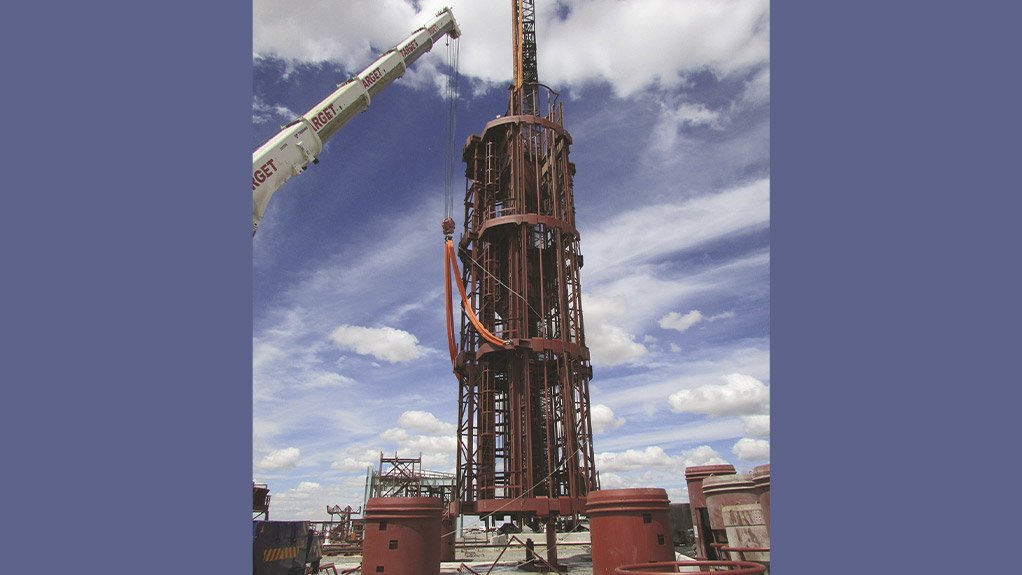

Cementation Africa demonstrates a specialist shaft sinking capability through the installation of a three deck stage into the pre-sink section of a shaft, carried out using heavy and tandem lifts by its in-house rigging and roping team

Cementation Africa’s in-house innovation sees a modified gantry crane used on multiple projects to support pre-sinking activities, hosting the sinking stage and kibble with enhanced flexibility, rapid deployment and automated, human-free tipping systems

Cementation Africa establishes robust underground infrastructure supported by strong maintenance strategies, in-house design capabilities and dedicated teams, delivering high quality life-of-mine solutions

Developed by Cementation Africa, this gantry crane enables safe and efficient pre-sink shaft operations and removes personnel from contact areas

Cementation Africa’s Bentley Park facility houses its Training Academy, strategic equipment warehousing and specialist refurbishment workshop, where underground machines are rebuilt with OEM involvement and warranty support, complemented by a dedicated field services rigging team

Cementation Africa combines advanced raise drilling and directional drilling expertise with the capability to remotely shotcrete shaft sections to depths of up to 200 m below surface, ensuring safe, accurate and efficient ventilation shaft construction

Combining its expertise as a shaft sinking and underground mining contracting contractor with its engineering capabilities and resources, Cementation Africa underpins the pace and safety of its projects with cost effective fleet management.

According to Arthur Adams, Manager Engineering at Cementation Africa, the company’s strategic fleet allows it to respond rapidly to specific project needs – while maintaining a high level of control over safety and performance standards.

“The balance between owning this strategic fleet and operating client-owned machinery gives us flexibility without the financial burden of depreciation of an underutilised equipment base,” Adams says.

The strategic fleet comprises a set of key assets that support infrastructure and shaft access work including winders and flameproof equipment for specialised applications such as box-cut development in coal mining.

“This disciplined approach directly supports our goal of achieving the best total cost of ownership for the fleet,” he says. “Intermediate and major rebuilds are timed strategically to maximise uptime while controlling long-term capital and operating costs.”

He highlights that the company uses its historical data and established formulas for its manning levels and maintenance cycles – fleet practices that contribute to productivity while controlling costs.

Significantly, Cementation Africa operates its own well-equipped engineering services and rebuild facilities, where refurbishment of both its own and clients’ machines is done to OEM specifications. This facility near Carletonville in Gauteng is also where the company’s world class Cementation Africa Training Academy is situated.

Cementation Africa’s approach is project-specific and collaborative, according to New Business Director, Graham Chamberlain, so the operating model does not rely on maintaining a centrally owned contract fleet.

“For each contract, we assess the mining method, production requirements and site conditions before selecting the most suitable equipment in conjunction with the client,” Chamberlain says. “In some cases, we purchase the equipment on behalf of the client, while in others the client procures this directly and we operate the equipment on their behalf.”

Ultimately, he explains, the equipment vests with the client since they fund its acquisition, but the Cementation Africa team’s input ensures that the machinery is optimally matched to the job at hand.

“There is usually a waiting period for new equipment so we build this into our project planning,” he says. “When clients do not have early access to equipment, we use ‘bridging’ equipment which are typically used items – and can often negotiate with OEMs for the timeous supply of equipment.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation